WPS approvals

The importance of the homologation of welding processes and welders.

A procedural approval is not suitable for welding any job.

Author: Nacho Chinchilla, Integration and Welding Engineering, Consulting and Training

Often, the idea is raised that “a welding certification serves for any job”. This concept is NOT real, and this is the case because the current certification standards UNE EN ISO 15614 Company Procedures, UNE EN ISO 9606 welder certification, and UNE EN 1418 Welding Operators have different process ranges that limit their scope of application.

This is defined by the PROCESS VARIABLES, which are the ones that mark the limits and ranges of the different conditions of the certification in terms of coverage limits.

There are many process variables that must be studied in order to focus the documentary and legal scope of company and worker certification,

All of them are separately restrictive variables that enable or disable certification, the most important of which are the following:

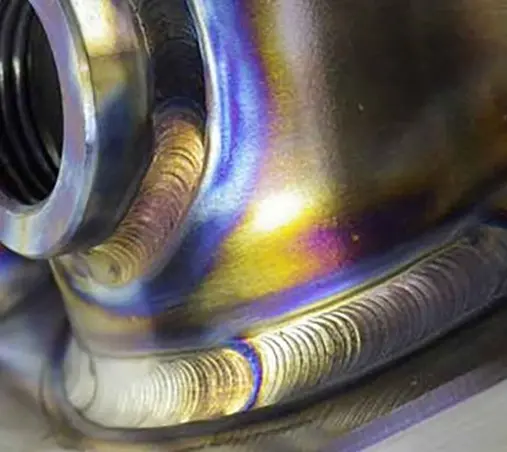

- Welding process (TIG, SMAW, MIG, MAG, SAW, PAW, etc.)

- Simple or mixed unions of several processes

- Type of base material and filler materials

- Carbon Steel, Stainless Steel, Aluminum, Etc.

- Even the quality of each material.

- Joints of dissimilar materials

- Type of welded joint, Plate or Tube.

- Butt or Angle Welding, Longitudinal or Perimeter.

- Total or partial welding position, Horizontal plane, Corsina, Under Ceiling, Vertical ascending or descending.

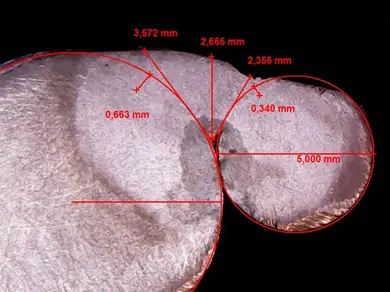

- Total or partial penetration, use of Backing, Resining, Welding on one or both sides, use of purge gases or auxiliary elements.

- Type of electric arc used

- Dimensions and arrangement of cords

- Carbon Steel, Stainless Steel, Aluminum, Etc.

For all these reasons, a complete technical study of the specific industrial need must be carried out.

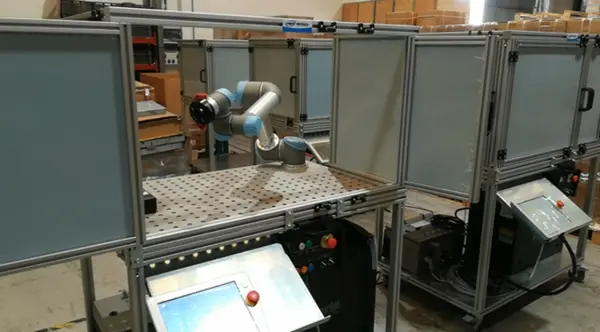

SynerBot Service. Approval and certification

Our experience and knowledge of the regulations and processes, will allow you to obtain the maximum possible coverage with the minimum investment, for which we will accompany you throughout the process of preliminary study, initial welding tests, and especially in the execution of the test coupons resulting from this study, to ensure the overcoming of all subsequent quality control with all laboratory tests that mark the reference standards, finally offering certification and approval documents that endorse third parties throughout this process.

For more information on this product, please contact us.

Share this post: