Technological innovation project

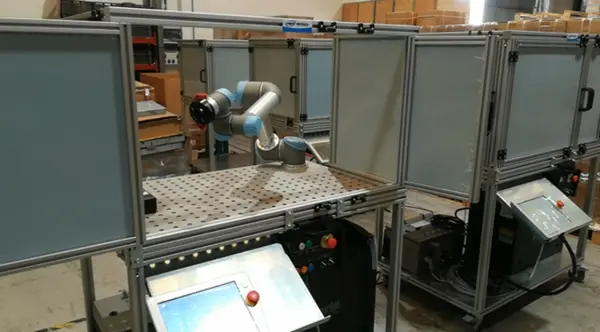

Traceability and total control of welding cycle parameters thanks to collaborative robotics using Synerweld special arcs, 3D computer simulation and industrial programming.

Project basis:

Grants for the implementation of innovation, applied research and knowledge transfer projects in the field of vocational training, funded by the Ministry of Education and Vocational Training – EU – Next Generation.

The first phase of the project was implemented with the delivery of equipment to participating schools.

The following schools participated: CIFP Tecnológico Industrial de León, IES José del Campo de Ampuero (Cantabria), CIFP Valentín Paz Andrade (Vigo),

CIFP Maintenance and Production Services in Langreo (Asturias) and GalaGar in Zaragoza

The first implementation and training process was carried out in each of the participating centers, to empower the teachers responsible for passing on information to the new generation of professionals who are to be the industrial backbone of the country’s present and future.

Une table autoportante complète avec une table de soudage, comprenant tout l’équipement de soudage et l’armoire de commande dans la partie inférieure, et le robot avec le disque de programmation et le couvercle de protection ainsi que la torche de soudage dans la partie supérieure ont été livrés.

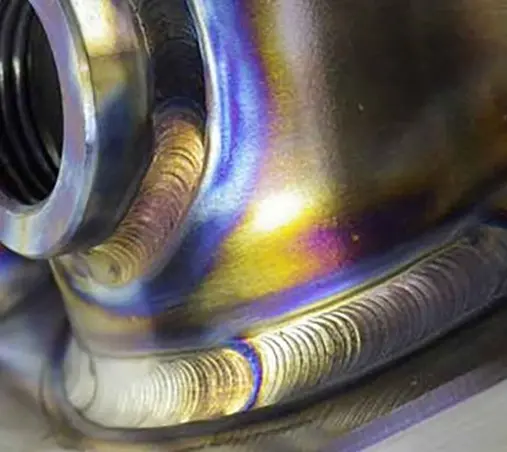

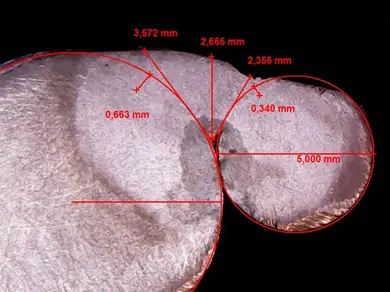

Welding equipment includes all types of special arc, SYNERWELDhttps://www.synerbotwelding.com/synerweld-series-arcos-de-soldadura/, that provide a wide variety of welding processes with high productivity improvements.

The table is equipped with lockable castors, spark trays, console and document holders, and movable windows with DIN11 inactinic protection for the protection of all personnel involved.

In addition, high-level eye protection was provided for the teaching staff, as well as a mobile extraction system with a hood to remove fumes, vapors and gases from the welding area, as well as fumes and gases from the material assembly processes.

The entire system was completed with software for management, computer programming and virtual recreation of welding processes.

Throughout this process and until the end of the innovation project in the early months of 2023, various technical and didactic tools will be provided, which will be enriched by video tutorials of various advanced programming applications recorded on site, in order to enhance the experience of using the equipment provided and increase the skills acquired, which will be extended with the implementation of a second phase.

A second phase of advanced training has yet to be implemented to complete this project, to enhance the skills and training of all teachers and improve their ability to implement training processes.

A fine performance and a fine project that enabled us to make our contribution to the training of future professionals.

For more information on this product, please contact us.

Share this post: