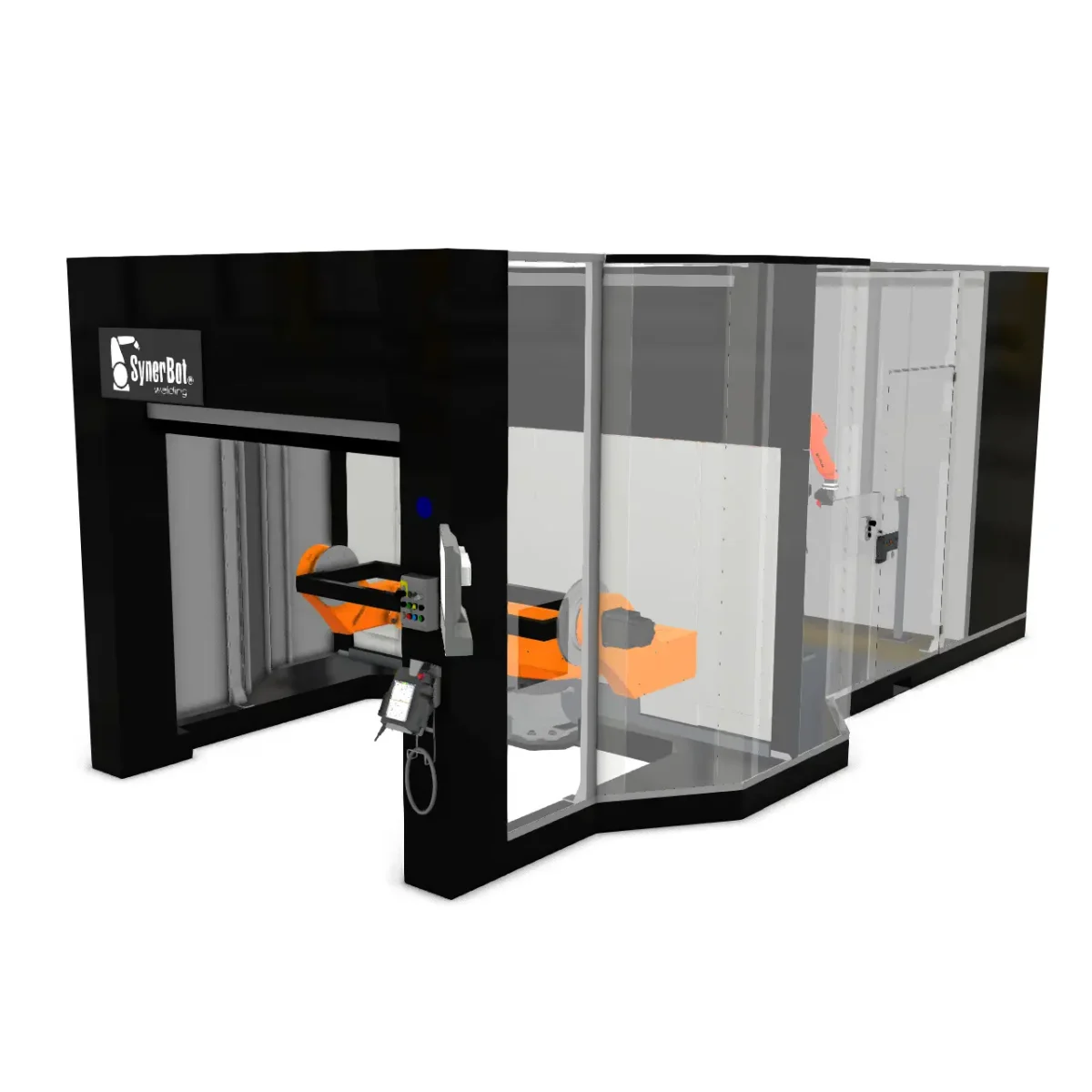

SYNERBOT SafetyCell AUTO TWIN 2MT

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high capacity welding, with two work areas at 180º which in turn have a lathe table for 360º part rotation, servo-controlled movements and integrated safety.

Features

- Complete welding equipment Synerbot 4000 / 5000 ADVANCED, with liquid-cooled torch, equipped with two independent working areas with 2.200mm lathe positioner with 360º rotation.

- Traffic light, cycle beacons on complete cell enclosure.

- Cell operation push button panel with safety mushroom.

- Torch cleaning unit (cutting, milling, anti-spatter).

- KUKA KR9 1440 robot with KRC5.

- Lift door for loading and unloading access and operator protection.

Applications

- Industrialization of small or large quantity series in any production sector.

- Movement and repositioning of parts synchronized with robot.

- Production plants, for continuous manufacturing without stops, and with high capacity cycle time