PS-3

These two guns allow precise welding of ignition tipped studs on traced surfaces or marked centres using the spring pressure of the gun.

PS-9

The PS-9 stud welding gun with an innovative user assistance system using a multi-colour LED display (patented utility model no.: 20 2009 012 370.7) has been designed for use with the new BMS-9 stud welding machine.

PS-1K

The handy and user-friendly PS-1K welding gun achieves extreme bolt positioning accuracies of +/- 0.1 mm thanks to precision mechanisms with sequences of movements that do not produce a backlash effect.

BMS-10N / BMS-10NV

High-performance equipment that can be used both manually and to make the leap to process automation, even with guns with automatic pin feed.

BMS-9 / BMS-9V

Inverter equipment that recognises the mains input voltage and the type of gun connected.

BMS-8N / BMS-8NV

Equipped with microprocessor and Digital display with parameter control.

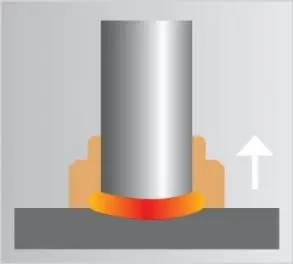

Synerbot and the Robotic Welding Revolution with Collaborative Robots

In the constant quest to improve and optimize production processes, the intersection of collaborative robotics and robotic welding marks a transformative milestone. Synerbot, as a leader in this innovation, is here to be the ally your company needs.

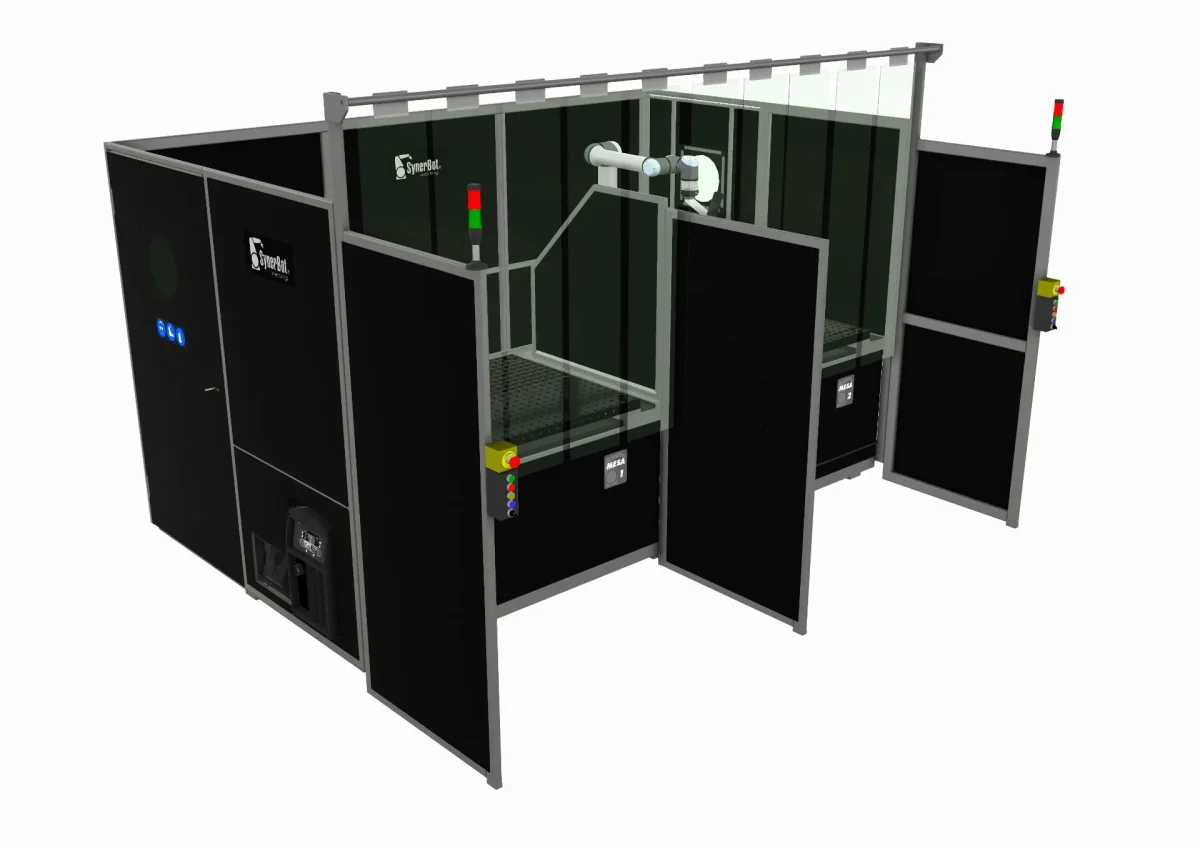

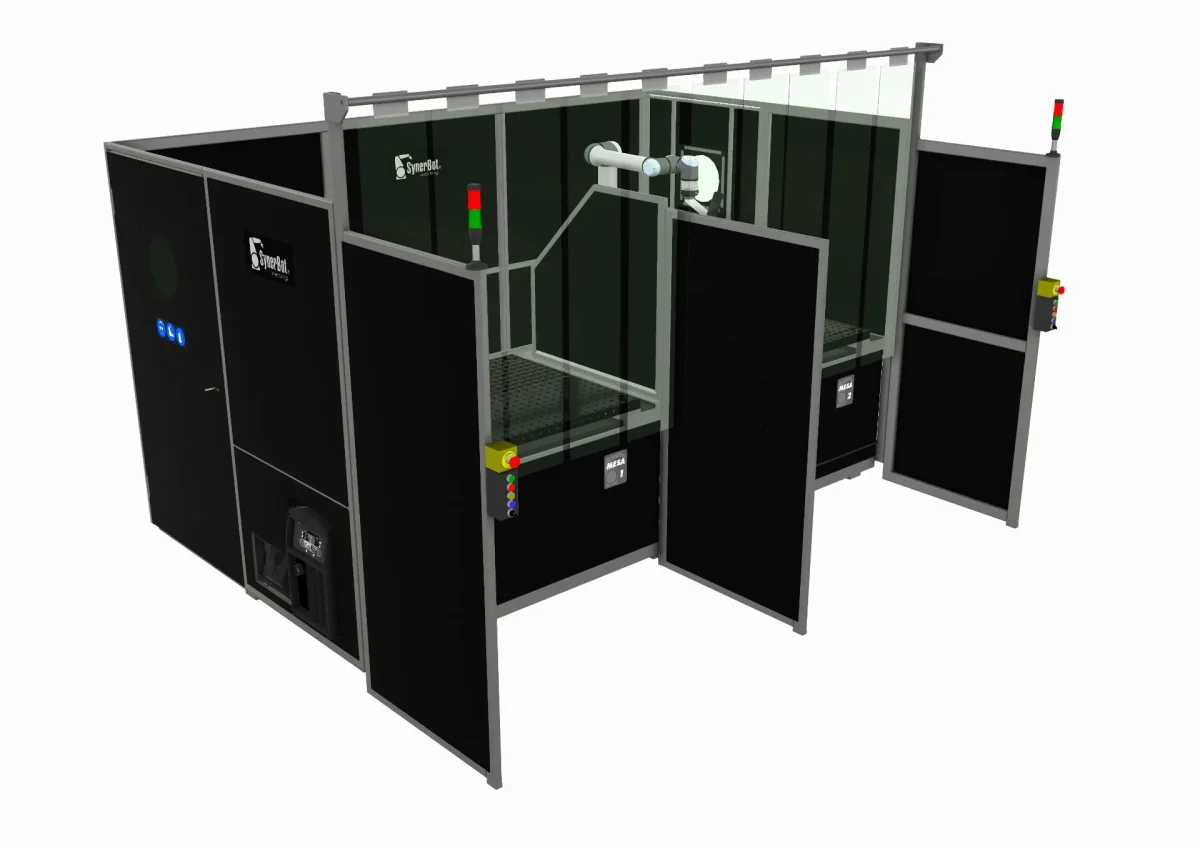

SYNERBOT FlexyCell M-twin

Cobot welding solution, self-supporting system, with two work areas at 180º, with manual turn-table systems, and integrated safety enclosure.

SYNERBOT FlexyCell Auto-twin

Cobot welding solution, self-supporting system, with two work areas at 180º, with automatic turn-table systems with safety enclosure and integrated photocells.

SYNERBOT FlexyCell Track-Twin

Cobot welding solution, with two working areas of 1500 x 1000 mm, or a single area of 3000 x 1200 mm, on the same plane, accessible by robot movement TRACK.

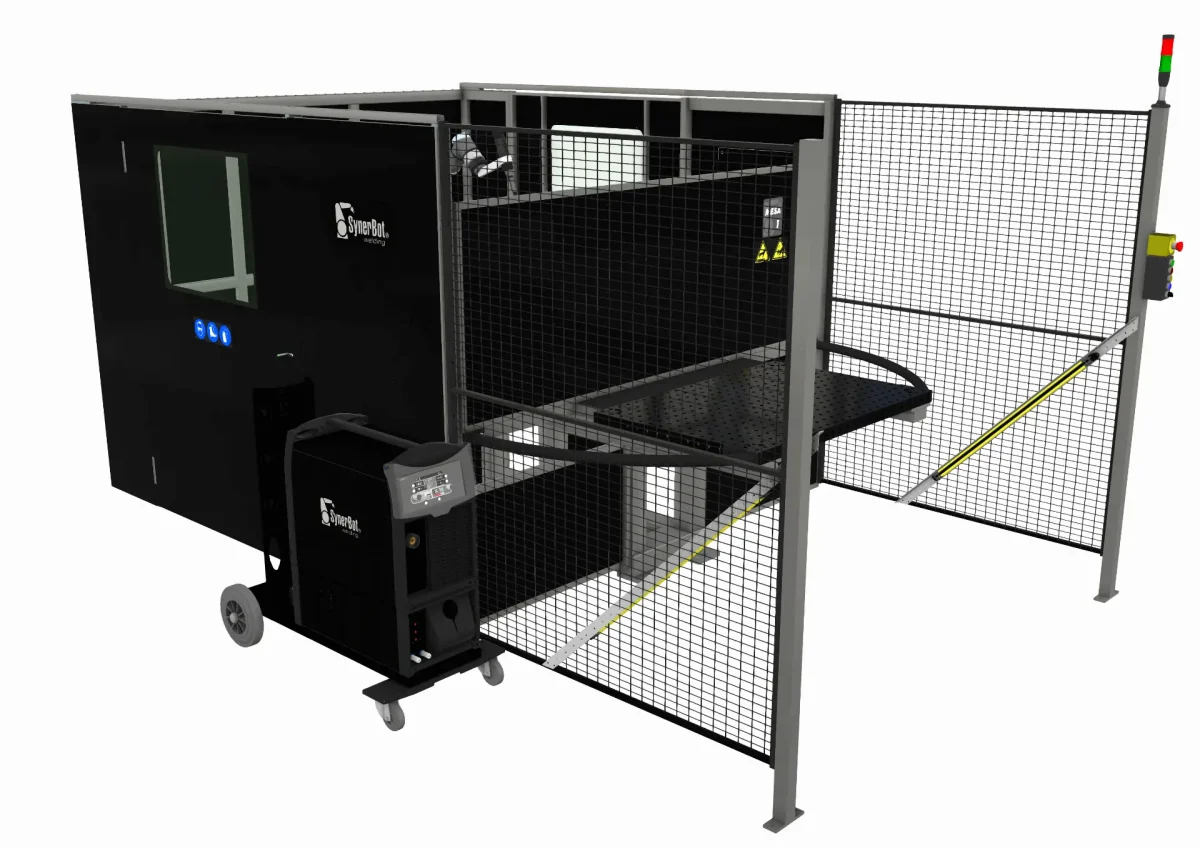

SYNERBOT EasyCell MF

Cobot welding solution, self-supporting system, with integrated safety systems.

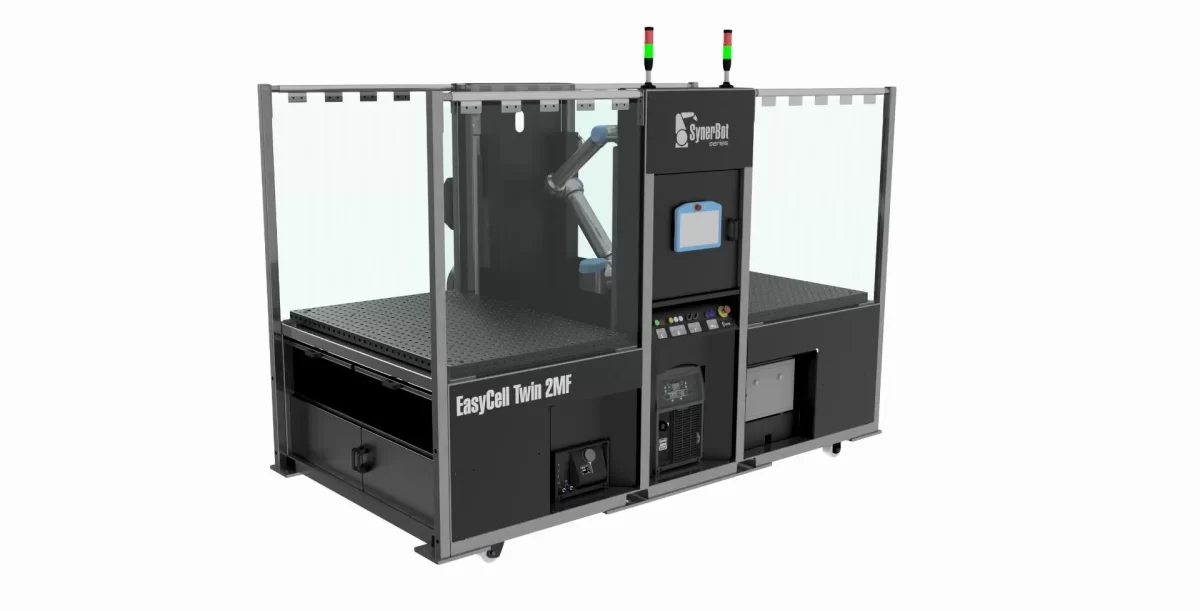

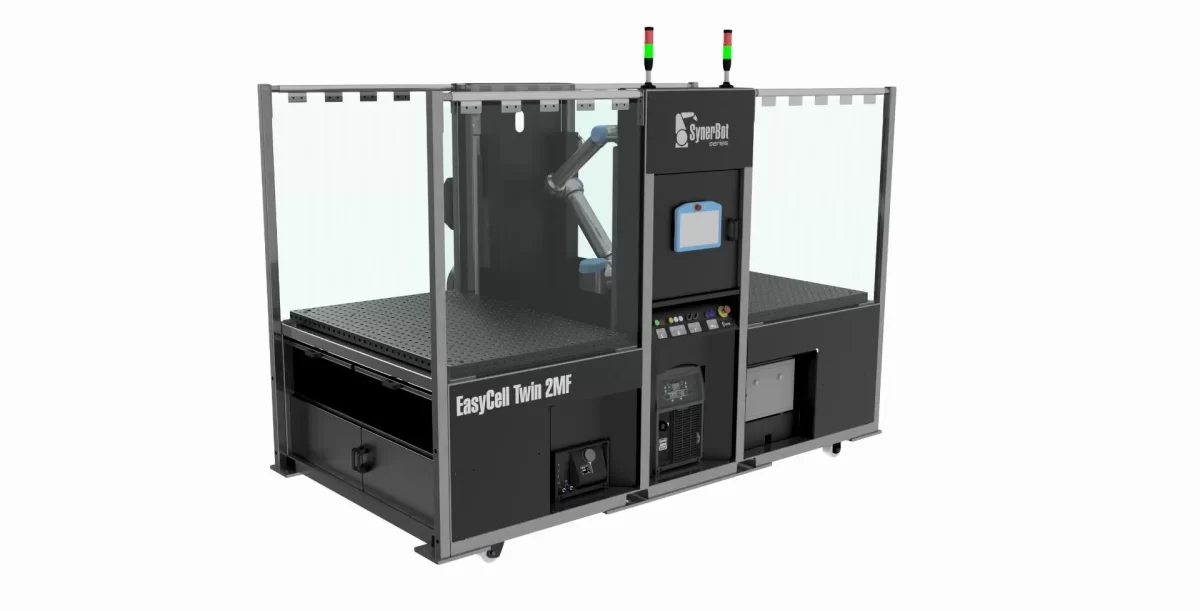

SYNERBOT EasyCell Twin

Cobot welding solution, self-supporting system, with two working areas at 180º, with integrated safety systems.

CompactCell: Efficiency Meets Simplicity

At Synerbot, we understand the importance of efficiency in industrial robotic welding. With CompactCell, we offer companies with large production runs and low numbers of different parts a solution that guarantees fast payback and high returns on investment.

- CompactCell Highlights

- Quick and Easy Integration: CompactCell is designed for seamless integration into your production facilities. Start seeing improvements in your welding process in no time.

- Superior Weld Quality: CompactCell offers exceptional weld quality and precise repeatability. Your production will meet the most demanding standards.

- Productive Time Control: CompactCell is designed to optimize productive times, which translates into efficiency and profitability for your company.

- Fast Return on Investment: CompactCell gives you the confidence that you will obtain high returns on investment in a short period of time.

With CompactCell, efficiency and quality in industrial robotic welding are guaranteed. If you are looking for a solution that simplifies your production process and improves your bottom line, CompactCell is the answer! Contact us today and find out how CompactCell can take your production to new levels.

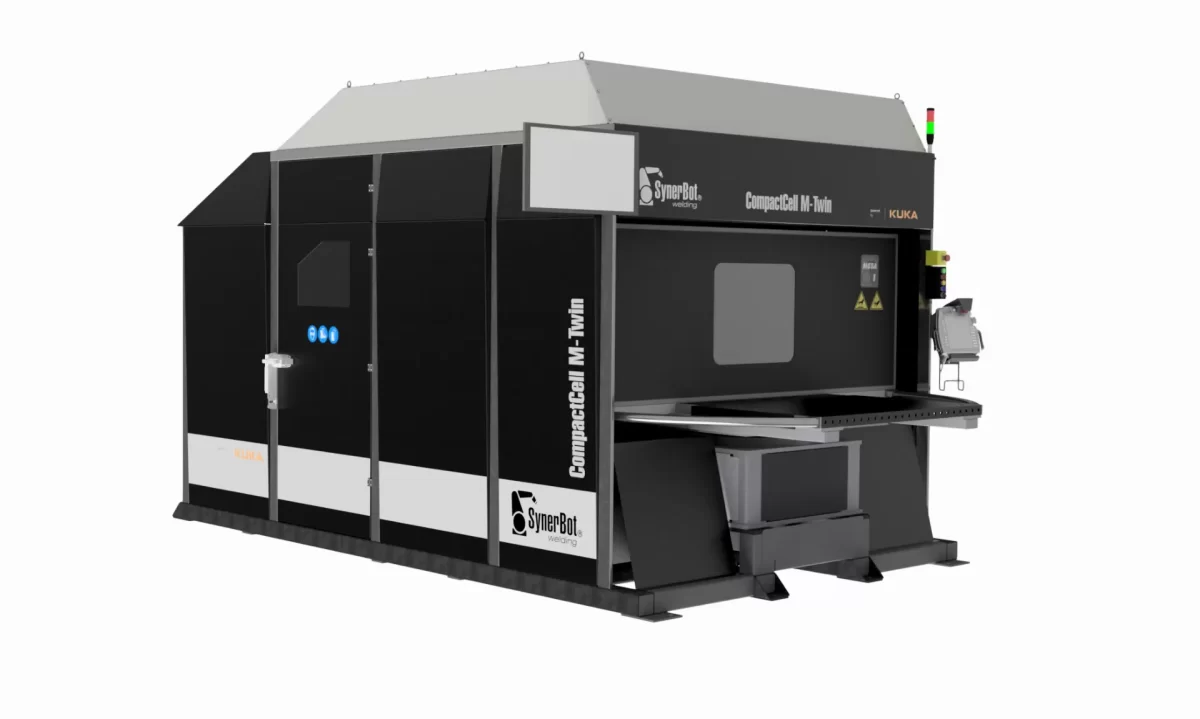

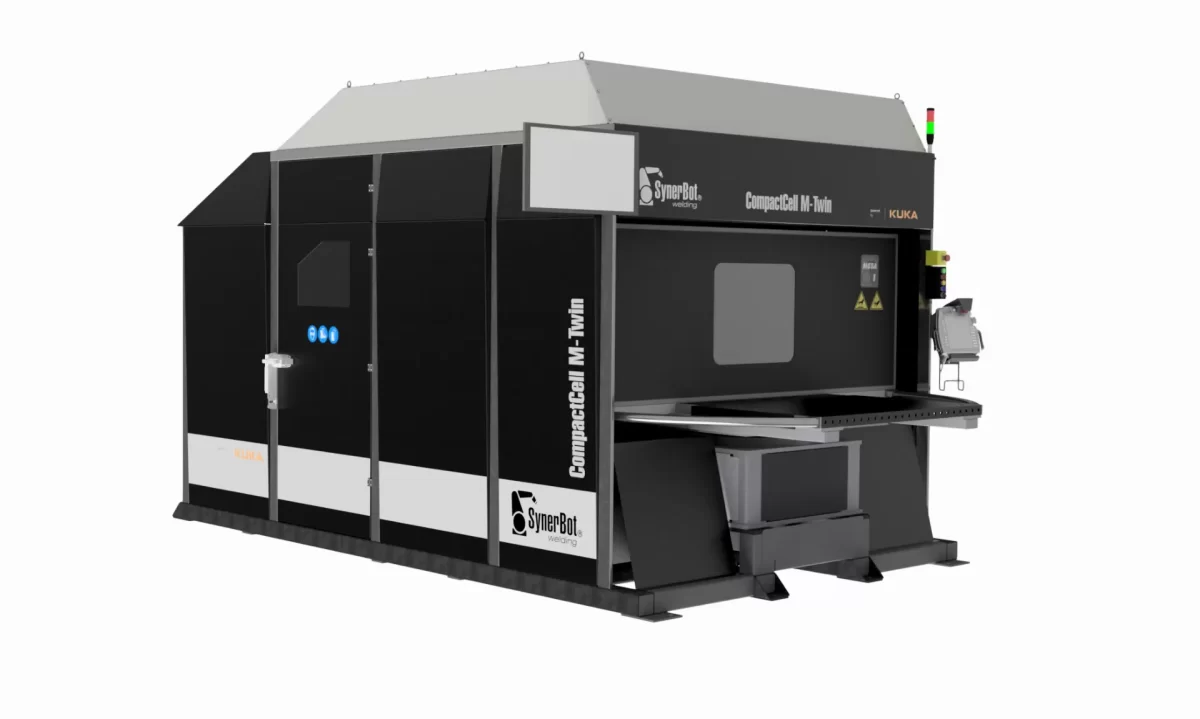

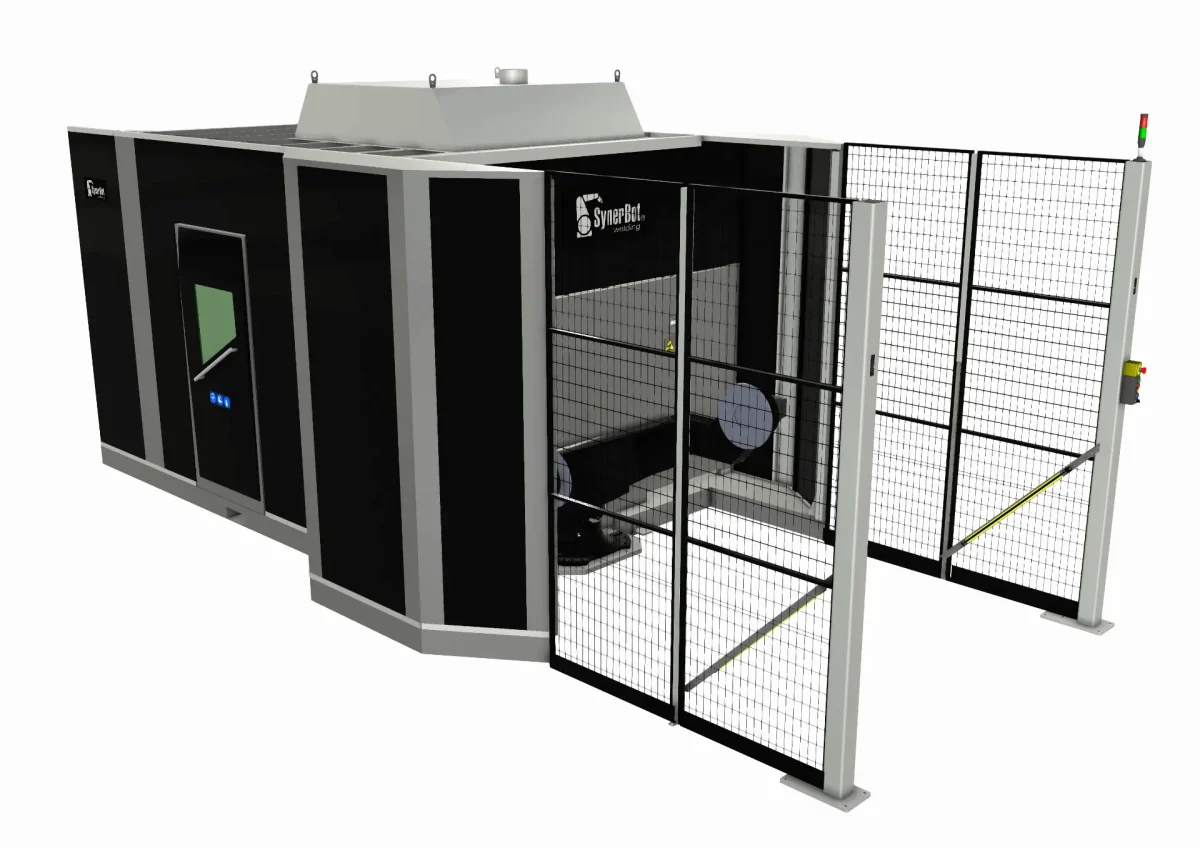

SYNERBOT CompactCell M-Twin

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high capacity welding, with two work areas at 180º, manual turn-table systems and integrated safety systems.

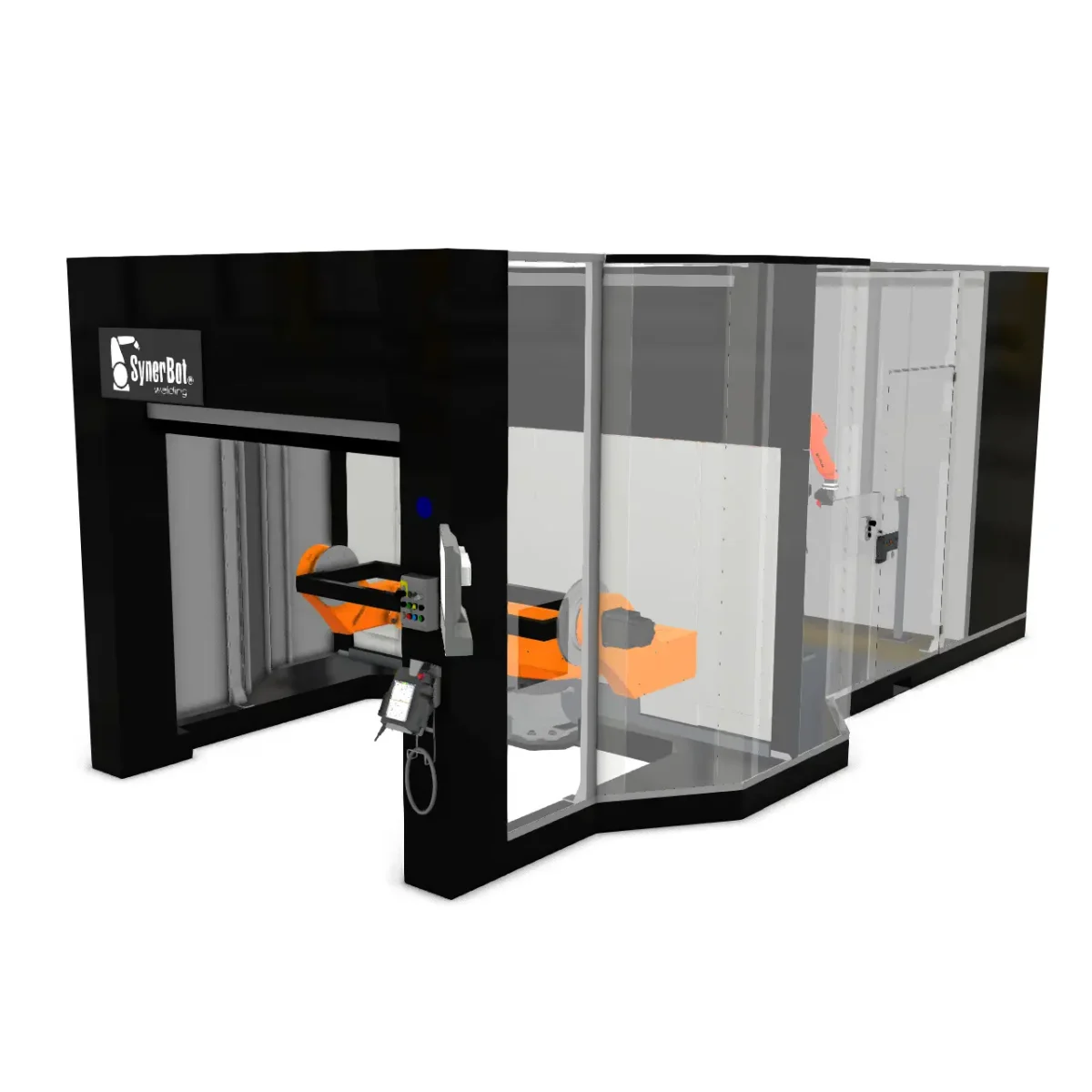

SYNERBOT CompactCell Auto-Twin

Welding solution in a self-supporting system, with two work areas at 180º, with automatic rotating table systems with safety enclosure and integrated photocells.

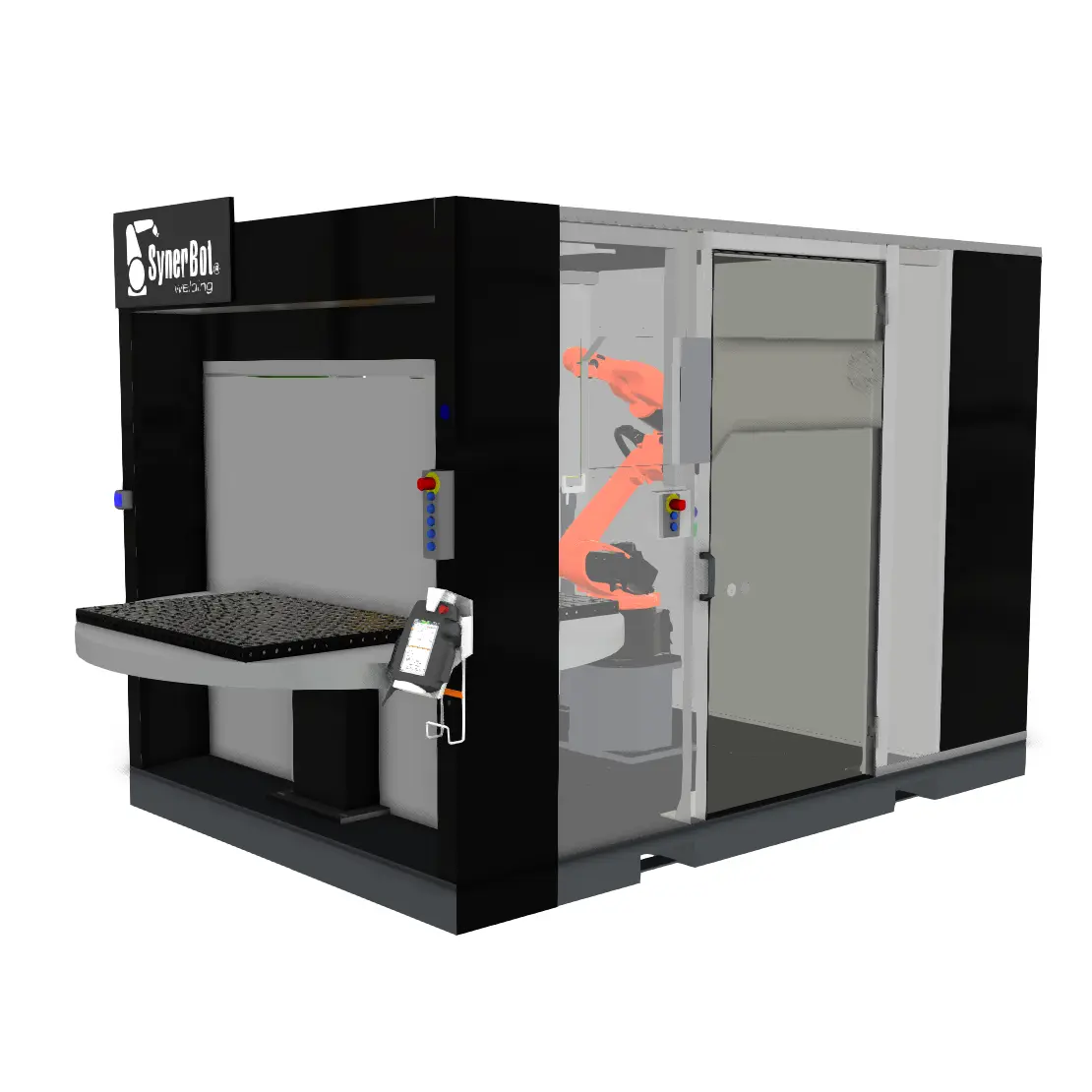

SYNERBOT CompactCell Auto-Twin MT

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high-capacity welding, with two 180º work areas which in turn have a lathe table for turning parts 360º, servo-controlled movements and integrated safety.

Welding arcs

Customize any synergic program.

EDITION

Customise, create or limit welding programmes. The incorporation of new materials, the use of quality systems or simply the incorporation of a new worker will directly affect our welding production.

BMK-16i

Multiprocess unit BMK-16i is a universal inverter power source recommended for different welding processes.

DA WELDING

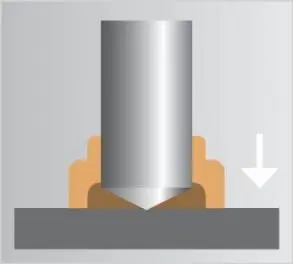

The “STUD WELD” welding process by means of ARCO, provides high quality and resistance in applications in connectors, bolts and terminals with diameters between 6 and 25 mm, providing solutions in construction, boilermaking, piping, etc.

- More info

PH3N

The user-friendly PH-3N stud welding gun offers a maximum of technical operating advantages thanks to its compact and very slim design.

BMK-12W

Easy to use equipment that can handle welding of bolts with diameters between 2 and 11 mm with metrics of M3-M12.

EasyCell: Smart Start in Robotized Welding

At Synerbot, we present EasyCell, the perfect solution for companies looking for robotic welding quality without the need for large production volumes. Our EasyCell cells are designed to ease the entry into the world of robotics with simple programming and quick learning.

- Easycell Highlights

- Collaborative Robots: Our EasyCell cells incorporate collaborative robots, which means they are safe and easy to work alongside humans. These intelligent robots are ideal for training environments, laboratories and short-run production.

- Flexibility and Adaptability: EasyCell is perfect for the production of high numbers of different parts and small-sized parts. These cells are designed to accommodate a variety of applications and production requirements.

- Fast Installation: We offer our customers a finished product ready to install in their production facilities. This means that from the first minute, you will notice significant improvements in your welding process.

- Guaranteed Quality: At Synerbot, we pride ourselves on delivering high-level robotic welding quality, even for those with smaller production needs.

With EasyCell, we bring affordable and efficient robotic welding to life. If you’re looking for a smart way to introduce robotics into your operation, EasyCell is the answer! Contact us today and find out how EasyCell can boost your production from minute one.

SYNERBOT EasyCell MF

Cobot welding solution, self-supporting system, with integrated safety systems.

SYNERBOT EasyCell Twin

Cobot welding solution, self-supporting system, with two working areas at 180º, with integrated safety systems.

FlexyCell: Your Partner in Versatile Robotized Welding

At Synerbot, we are committed to providing high-quality, versatile robotic welding solutions. With FlexyCell, we offer companies an ideal option to meet a wide range of production needs, even if they do not have large volumes.

- FlexyCell Highlights

- Collaborative Robots: FlexyCell’s collaborative robots are safe and easy to program. They are the smart choice for training centers, laboratories, prototyping and short-run production.

- Total Adaptability: FlexyCell is designed to accommodate a variety of applications, including the production of a high number of different parts and small-sized parts. You can count on FlexyCell to meet your specific requirements.

- Trouble-Free Installation: We offer our customers a finished product that installs quickly and easily in their production facilities. This means that from day one, you will see noticeable improvements in your welding process.

- Superior Quality: At Synerbot, we take pride in guaranteeing top-notch robotic welding quality, regardless of production volume.

With FlexyCell, we make you a true robotic welding expert. If you want a versatile and powerful solution, FlexyCell is the right choice! Contact us today to learn more and find out how FlexyCell can boost your production and quality.

SYNERBOT FlexyCell M-twin

Cobot welding solution, self-supporting system, with two work areas at 180º, with manual turn-table systems, and integrated safety enclosure.

SYNERBOT FlexyCell Auto-twin

Cobot welding solution, self-supporting system, with two work areas at 180º, with automatic turn-table systems with safety enclosure and integrated photocells.

SYNERBOT FlexyCell Track-Twin

Cobot welding solution, with two working areas of 1500 x 1000 mm, or a single area of 3000 x 1200 mm, on the same plane, accessible by robot movement TRACK.

Synerbot: Leading Innovation in Industrial Robots

Technological advancement and digitalization have redefined the manufacturing industry. In this evolving landscape, Synerbot is positioned as the preferred choice for those looking for cutting-edge industrial robots, specialized in robotic welding. Through this article, you will discover why our product range is essential for your company.

SYNERBOT CompactCell M-Twin

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high capacity welding, with two work areas at 180º, manual turn-table systems and integrated safety systems.

SYNERBOT CompactCell Auto-Twin

Welding solution in a self-supporting system, with two work areas at 180º, with automatic rotating table systems with safety enclosure and integrated photocells.

SYNERBOT CompactCell Auto-Twin MT

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high-capacity welding, with two 180º work areas which in turn have a lathe table for turning parts 360º, servo-controlled movements and integrated safety.

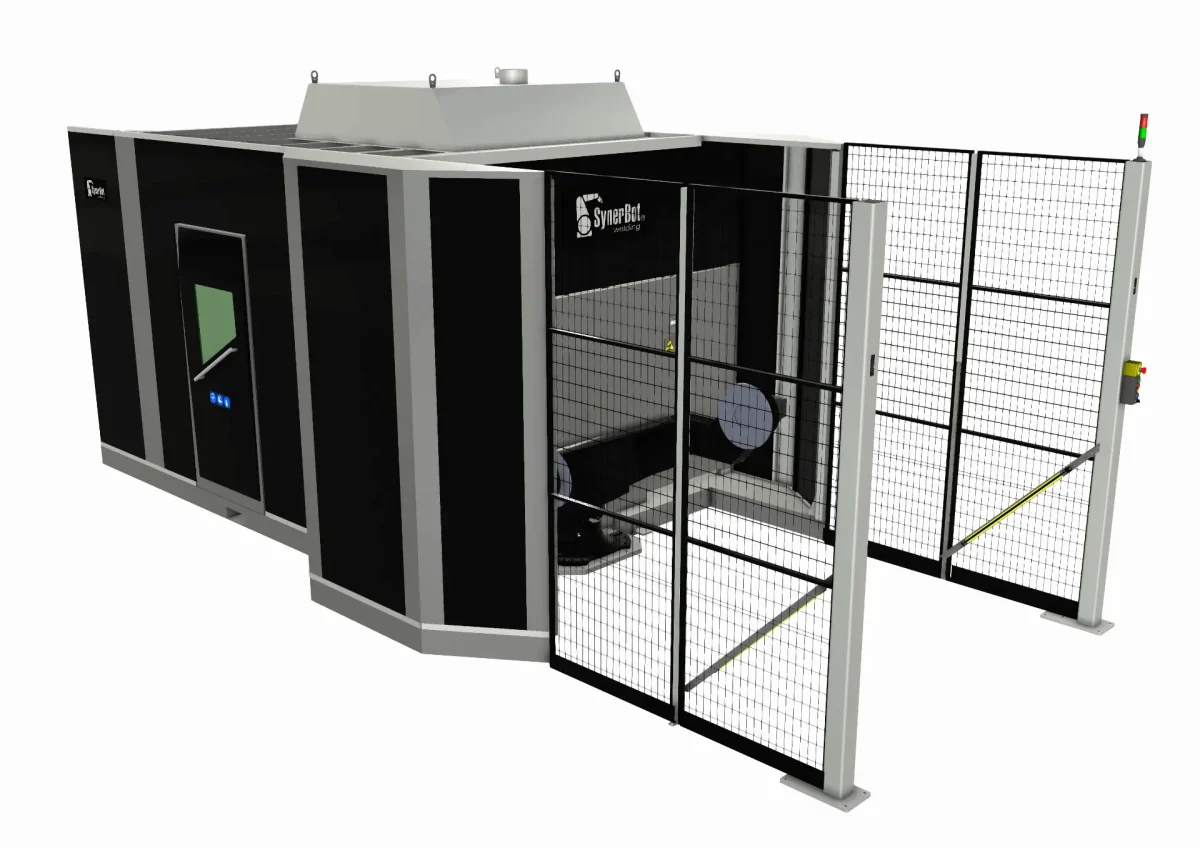

SYNERBOT SafetyCell AUTO TWIN 2MT

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high capacity welding, with two work areas at 180º which in turn have a lathe table for 360º part rotation, servo-controlled movements and integrated safety.

SYNERBOT SafetyCell AUTO TWIN COMPACT 2MF

Self-supporting and compact cell with complete perimeter enclosure and roof, designed for high capacity welding, with two work areas at 180º, automatic turn-table systems with integrated safety systems.

SYNERBOT SafetyCell AUTO TWIN 2MF

Welding solution in self-supporting system, with two work areas at 180º, with automatic turn-table systems with safety enclosure and integrated photocells.

MAKE IT EASY

They facilitate the execution of welding.

CEILING

Welding in an overhead position. Welding in an overhead position is inevitably affected by the effects of gravity, therefore, the execution operation requires adapting the torch movements to the melting point of the bath.

SPEED UP +

For all those who want more, and with specific application in carbon steels, SPEED UP + is an arc evolution with respect to SPEED UP. Combining two much more concentrated arcs, we obtain vertical upward welding speeds of up to 4mm/s. (4'10" linear metre).